DOLPHIN (Disruptive pemfc stack with nOvel materiaLs, Processes, arcHitecture and optimized Interfaces) focused on developing innovative fuel cell manufacturing processes and architectures to enhance PEMFC (Proton Exchange Membrane Fuel Cell) stack performance for automotive applications in terms of durability, weight and volumes, therefore improving the power density.

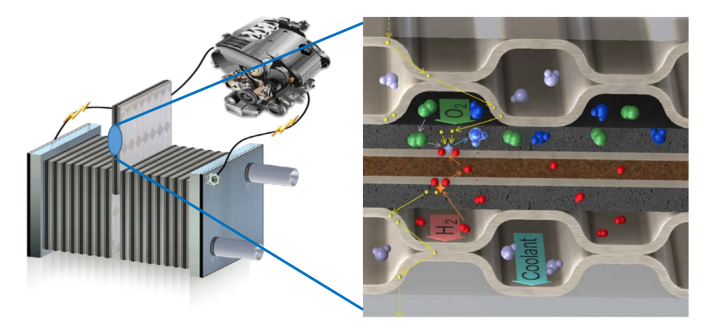

The project introduced the concept of a dual-core cell architecture, comprising:

- The Electric and Fluidics Core (EFC), responsible for fluidic and electronic conduction.

- The Electrochemical Core (EC), which handles electrochemical functions, including mass and charge transport.

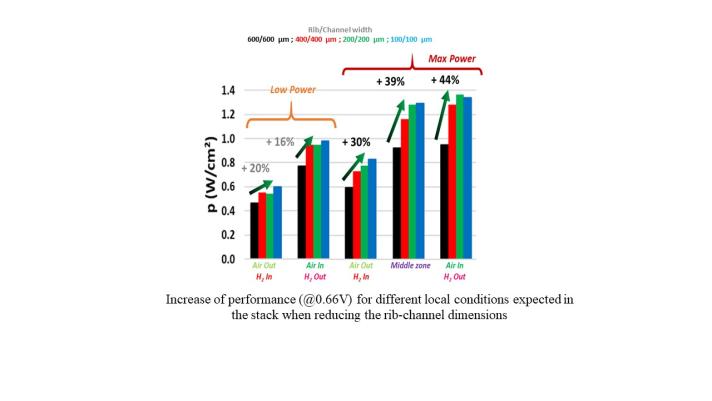

The goal of separating the cell design in two cores is to reduce ionic and electrical resistance within the cell and mass transport losses. Multiple manufacturing techniques have been used to improve the design of both cores, culminating in the development of two short stacks. Both short stacks included improved Dolphin ECs incorporating advanced components developed during the project. Each stack also included stack-specific EFCs based on the most promising flow-field design techniques namely, additive manufacturing and GDL machining.

The results indicate that:

- the short stack with additive manufacturing could reach the highest performance in terms of area-specific power density (up to 1.97 W/cm² at 3 A/cm², at cell level), an improvement of approximately 100% versus the state of the art,

- while the short stack with GDL machining could reduce the weight and volume of the stack, foreseeing gravimetric and volumetric power densities at stack level above 4kW/kg and above 5kW/liters respectively, an improvement of approximately 20% versus state of the art.

The DOLPHIN stack has been designed for a 100kW target application, typical for the automotive sector. In the future, the technologies developed by Chemours using their membrane/ionomer and CEA ink formulation will have to be integrated into Symbio manufacturing processes at scale, in order to bring the DOLPHIN stack to the market.

Project webpage: https://www.dolphin-fc.eu/